Scale Matters

Orin shows off the F-84E Thunderjet as it looked in July 2014. All photos by Orin Humphries.

Copiers and French curves

By Orin Humphries

January 2015

Copiers

Things are moving along on the F-84.

I have been interrupted by the refurbishing of our house, now 20 years old. That wasn't the half of it. The -84 Project threw me yet another curve ball. When building up the upper half of the fuselage as the starting point on the top view I had, I discovered that a handful of frame halves were distorted a bit. I chose to push on just sanding and filling as required.  But further investigation revealed that some 80% of the frames had some degree of distortion, the worst two were 0.100” off and 0.095” off in some sector. How had that happened?

But further investigation revealed that some 80% of the frames had some degree of distortion, the worst two were 0.100” off and 0.095” off in some sector. How had that happened?

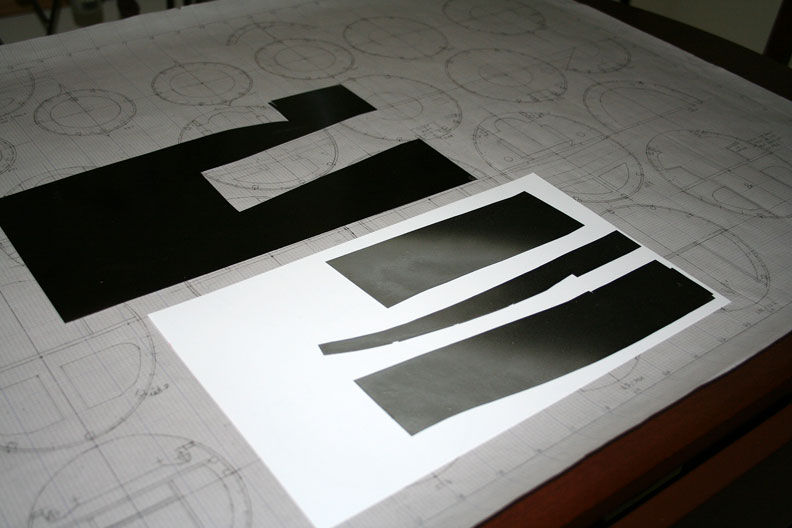

As you may know, I had my original 1/12 scale enlarged at a commercial graphics house to 110% to lower my wing loading. The graphics scanner/printer at the local office store was putting out 101% when told to make it 100% (for the record copy). I could have punched in 99% and made good enough, but I chose to go to a commercial printing house where I am afforded a price break. First, the 10% enlargement had vertical and horizontal scales that were not the same by a bunch. They adjusted their machines. The second try looked good and I had a second copy made at the larger scale to cut out and glue to the wood stock. Upon assembly I discovered that the cross-section/frame patterns were distorted. The printer head was not moving uniformly across the paper. Now it was a question of how much time to topically correct that many frames or to draw the enlargements from scratch. The clincher was that if the frames were distorted, how good was the top view over which I was building the fuselage? It turned out, sadly, that the centerline of the enlargement was bowed to the right. I would have built a C-shaped fuselage upon it. Sigh.

My next move was to revisit the office supply store and try their machine with a tweaked enlargement setting. Their vertical scale did not match the horizontal scale by 5/16” at the end of 22”. I pointed this out to the manager who had a look of bewilderment on his face.

I spoke with a young man who is also a docent at the Historic Flight Foundation where I now volunteer. He is studying graphic arts at a local school. When I told him of my travails with copiers, he asserted, “All copiers are that way.” The main customers for those copier outputs are architectural folks or other graphics operations. These do not required 1:1 fidelity. Only we scale modelers and such extremely rare types these days do.

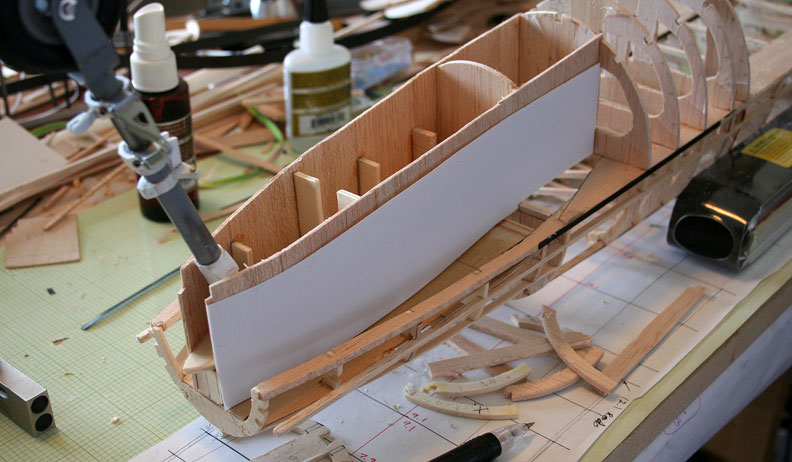

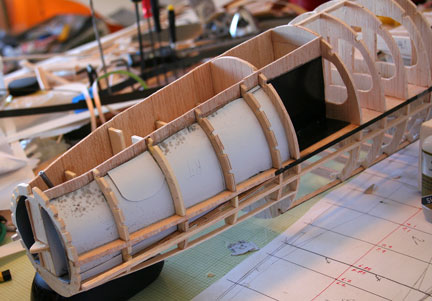

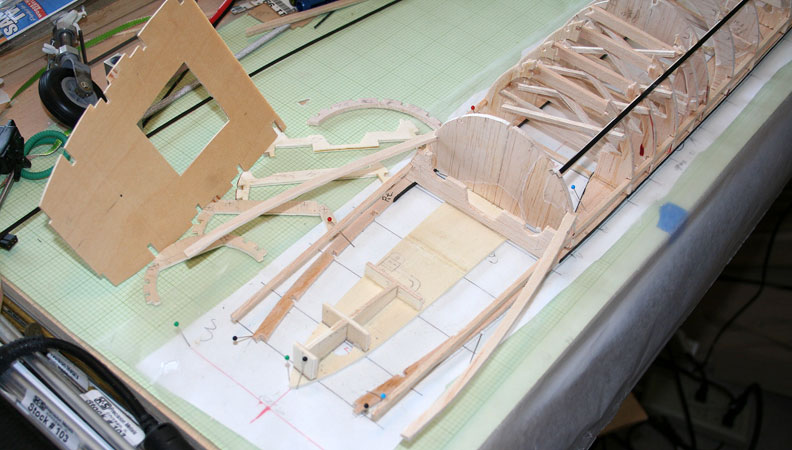

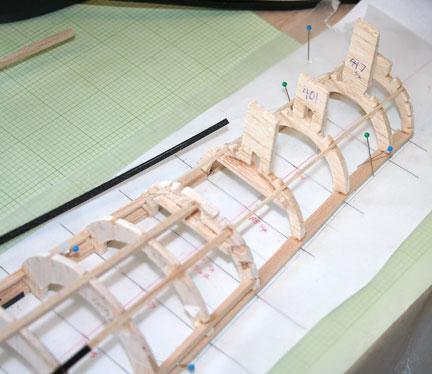

With the new manual drawings complete and two months of my life gone, I started over. The other day I took the second fuselage off the drawing board and a photo of it is at left.

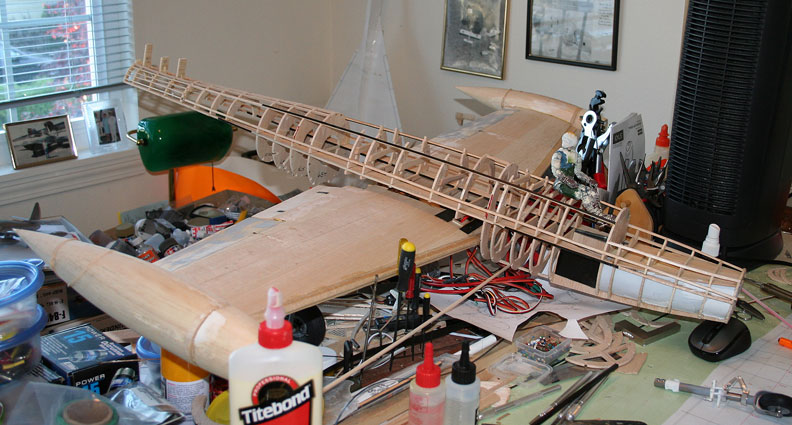

This project has a jigsaw puzzle for a nose with a gun bay above the nose wheel well and air ducts to either side of the well. Actually, it went together much better than I was afraid of before I got my hands on the parts. Some photos of that are included at the bottom of the column. I painted the air duct walls, made from .010”t. styrene sheet, all black first to simulate shadow in the ducts, and then over-sprayed aluminum at the front ends of the pieces. When the judges look into the ducts, they will “see” aluminum fading out in the dark.

All the lower frame halves are in place save for under the empennage. Now, I need to make and install the pushrod and the tailpipe which have to go in together. The pushrod penetrates the tailpipe from the inside out as it goes from the mid-mounted wing to the raised tail.

I took a picture of the fuselage sitting atop the wing just for looks and grins. It is below.

French curves

Two years ago I bought some more triangles and French curves at the University of Washington bookstore. One was a huge 45° triangle for putting borders on new drawing sheets. The long edge of the triangle turned out not to be a straight edge. Lately I bought a larger French curve for the frames drawings. Its edge had a deviation from smooth, “wiggle” in it. Close examination of the edge of the curve revealed the problem. Today these drawing aides are hand made in China. If you turn the curve on edge and catch the light on it, you will see mini-scallops left by the router cutting edges. The hands of the worker who, made these, deviate from “True” because they are human, too. Inspecting my older curves I discovered that in days gone by these aides were injection molded into high quality molds.

Historic Flight Foundation

At the Foundation, we had a veritable airplane fairyland last year. The B-29 spent two weeks at our place and underwent its 50-hour check before leaving. (They changed spark plugs on No. 2.) There were many engine starts to see and hear. A photo of the ramp is below.

The foundation owner, Mr. John Sessions, had pulled the F7F Tigercat out of the hangar on the last day of the B-29's visit and fired it up, or tried to. I swear, its No.2 was running out its prime, just like a model engine. But that is a P&W R2800! When it quits the sound stoppage is SHARP! Finally he got the switchology sorted out and it stayed running. That I dreaded. The F7F has no firewall aft of the accessory compartment and those big engines seep a lot of oil when they have not been run for a while and the seals shrink and loosen up. Oil gets everywhere inside clear back to the tip of the nacelles, on the landing gear, everything! Somebody has to clean all that oil up. Thankfully, it would be six more days before my next shift, there, and others ahead of me would get that task. I have done it once. Yet, you lose your audience when you whine about having to clean oil out of an F7F. This pretty well defines the saying, “No sympathy.”

A few days later, I directed the parking of our returning T-6 into the hangar beside eight other priceless airplanes, between the F8F Bearcat and the F7F Tigercat named "Bad Kitty". The T-6 had been away as part of a four-plane formation flight at the Arlington Airshow.

The next day, at closing time, I climbed alone into the cockpit of our B-25D, “GRUMPY,” and sat in the left-hand seat for a moment. I figured out how to operate the sliding window closures to button up the airplane for the night. On my way out I stared at the North American Aviation logo cast into the rudder pedals. Then I clambered down the ladder designed for 20-year-olds and closed both the front and rear crew hatches. On the way back toward the hangar, I saw that another docent, Doug, was struggling with closing the stair door on the DC-3. I was glad to let that slightly younger man do that as it has an oleo strut to restrict its movement.

My last tour for that day had been for a pair of men. One of them had been the head of a major field operation, a huge piece of history, for an agency we cannot name. How I wish he could have told me any of his activities! But for security reasons, he was unable to utter a single word. That's my story and I am sticking to it. (I love this job!)

More photos of the F-84E project

Flying Lines home page

Back to Scale Matters column main page

Back to Scale main page

This page was upated Jan. 10, 2015